|

|

#define AC (UINT)1

#define BC (UINT)2

#define A4 (UINT)3

#define B4 (UINT)4

typedef struct

{

double x, y, z, a, b, c; //输入x,y,z,a,b,c

double x5, y5, z5; //保存第五轴x,y,z,a,b,c

double X, Y, Z, A, B, C; //保存计算结果x,y,z,a,b,c

double g55x, g55y, g55z; //保存旋转轴中心线交点的机床坐标位置G55

double g56x, g56y, g56z; //保存用分中棒抓取的工件坐标位置G56

double tlen; //刀具长度

}rtcp_t;

typedef struct

{

double a, b, c; //输入a,b,c

double X, Y, Z, A, B, C; //保存G54最终计算结果

double g55x, g55y, g55z; //保存旋转轴中心线交点的机床坐标位置G55

double g56x, g56y, g56z; //保存用分中棒抓取的工件坐标位置G56

}g54_t;

typedef struct

{

double a, b, c; //旋转轴角度配置

}offset_t;

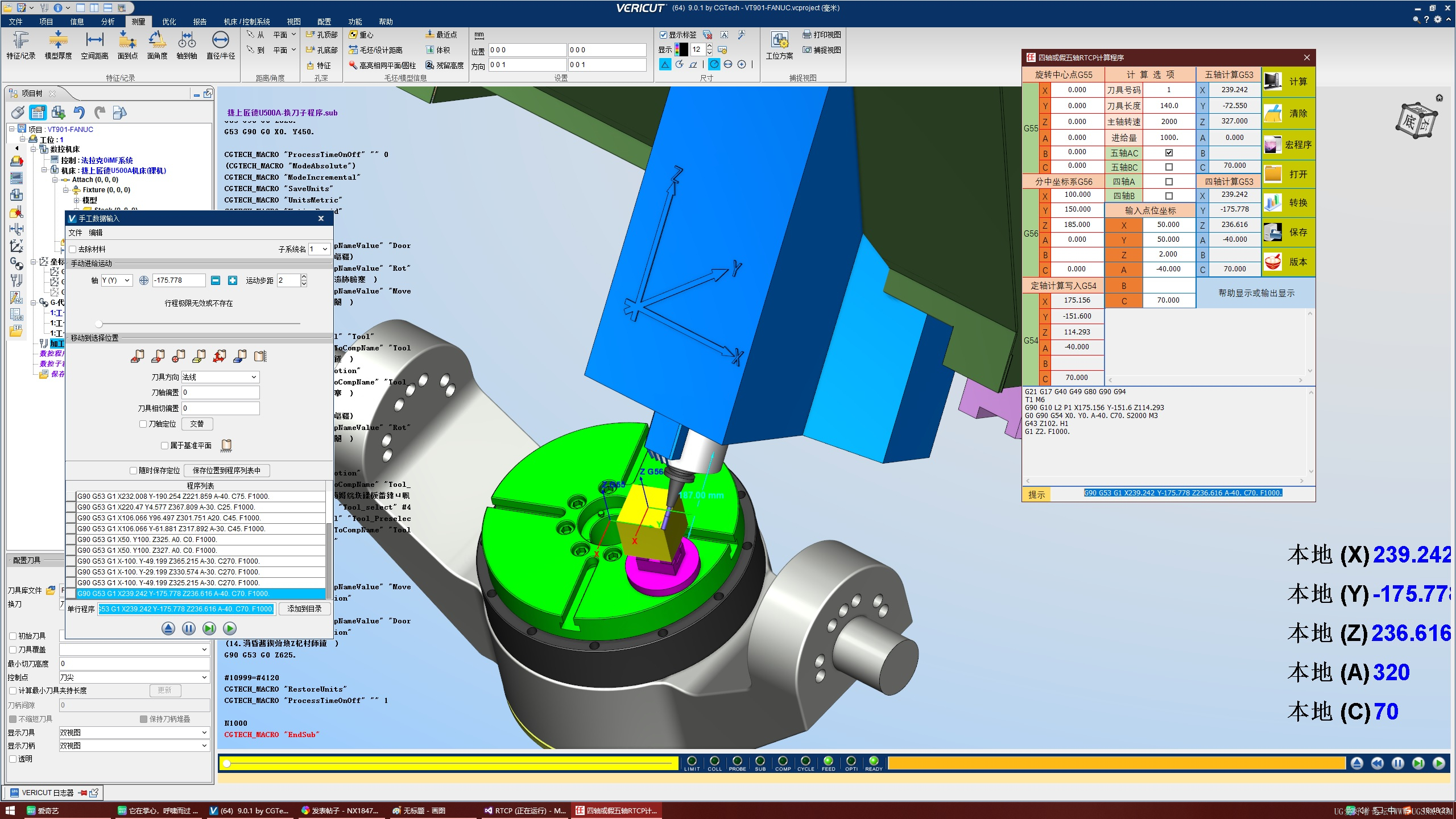

3+2定轴算法:

BOOL g54_fixed_axis_algorithm(g54_t* p, offset_t* pOffset, UINT type)

{

if (!p || !pOffset || type < AC || type > B4) return FALSE;

double x, y, z, x4, y4, z4, x5, y5, z5;

double sin4, cos4, sin5, cos5;

switch (type)

{

case AC:

sin4 = -1.0*sin(p->a*rad);

cos4 = cos(p->a*rad);

sin5 = -1.0*sin(p->c*rad);

cos5 = cos(p->c*rad);

break;

case A4:

sin4 = sin(-(p->a)*rad);

cos4 = cos(p->a*rad);

sin5 = 0.0;

cos5 = 1.0;

break;

case BC:

sin4 = -1.0*sin(p->b*rad);

cos4 = cos(p->b*rad);

sin5 = -1.0*sin(p->c*rad);

cos5 = cos(p->c*rad);

case B4:

sin4 = sin(-(p->b)*rad);

cos4 = cos(p->b*rad);

sin5 = 0.0;

cos5 = 1.0;

break;

}

x5 = p->g56x - p->g55x;

y5 = p->g56y - p->g55y;

z5 = p->g56z - p->g55z;

//5 axis calclate:

x4 = x5*cos5 - y5*sin5;

y4 = x5*sin5 + y5*cos5;

z4 = z5;

//4 axis calclate:

switch (type)

{

case AC:

case A4:

x = x4;

y = y4*cos4 - z4*sin4;

z = y4*sin4 + z4*cos4;

break;

case BC:

case B4:

x = x4*cos4 + z4*sin4;

y = y4;

z = z4*cos4 - x4*sin4;

break;

}

p->X = x + p->g55x;

p->Y = y + p->g55y;

p->Z = z + p->g55z;

p->A = p->a + pOffset->a;

p->B = p->b + pOffset->b;

p->C = p->c + pOffset->c;

return TRUE;

}

五轴联动刀尖跟随RTCP算法:

BOOL g53_rtcp_algorithm(rtcp_t* p, offset_t* pOffset, UINT type)

{

if (!p || !pOffset || type < AC || type > B4) return FALSE;

double x, y, z, x4, y4, z4, x5, y5, z5;

double sin4, cos4, sin5, cos5;

switch (type)

{

case AC:

sin4 = -1.0*sin(p->a*rad);

cos4 = cos(p->a*rad);

sin5 = -1.0*sin(p->c*rad);

cos5 = cos(p->c*rad);

break;

case A4:

sin4 = -1.0*sin(p->a*rad);

cos4 = cos(p->a*rad);

sin5 = 0.0;

cos5 = 1.0;

break;

case BC:

sin4 = -1.0*sin(p->b*rad);

cos4 = cos(p->b*rad);

sin5 = -1.0*sin(p->c*rad);

cos5 = cos(p->c*rad);

case B4:

sin4 = -1.0*sin(p->b*rad);

cos4 = cos(p->b*rad);

sin5 = 0.0;

cos5 = 1.0;

break;

}

x5 = p->g56x - p->g55x + p->x;

y5 = p->g56y - p->g55y + p->y;

z5 = p->g56z - p->g55z + p->z;

//5 axis calclate:

x4 = x5*cos5 - y5*sin5;

y4 = x5*sin5 + y5*cos5;

z4 = z5;

p->x5 = x4;

p->y5 = y4;

p->z5 = z4 + p->tlen;

//4 axis calclate:

switch (type)

{

case AC:

case A4:

x = x4;

y = y4*cos4 - z4*sin4;

z = y4*sin4 + z4*cos4;

break;

case BC:

case B4:

x = x4*cos4 + z4*sin4;

y = y4;

z = z4*cos4 - x4*sin4;

break;

}

p->X = x; //机械坐标X

p->Y = y; //机械坐标Y

p->Z = z + p->tlen; //机械坐标Z偏移一个刀长

p->A = p->a + pOffset->a; //机械坐标a偏移一个偏置a

p->B = p->b + pOffset->b; //机械坐标b偏移一个偏置b

p->C = p->c + pOffset->c; //机械坐标c偏移一个偏置c

return TRUE;

}

|

|